Top Four Benefits of Using a Hand Stretch Film

When selecting the right packaging solutions for your business, pinpointing the best leads can be frustrating. You will have to consider different products, which means that you need to come up with universal solutions for all the products. A hand stretch film is regarded as one of the most practical packaging solutions ever invented.

Choosing the right packaging solution ensures that every product receives better packaging treatment and there are no wastages. That’s when a hand stretch film comes into the picture.

Aside from the universal application and advantages of stretch film, the wrapping material has incredible benefits that are discussed below:

Cheaper in the Long Run

The availability of funds is one of the most common reasons why organizations switch from one product to another. Packaging can become a very expensive affair if proper materials are not used. Apart from the cost, your business also runs the risk of wastage if the materials you are currently using are not as effective. If that is the case for your business, then it is time you considered using a stretch wrap film. You will be able to save about 40% of what you are using and that is just a small scale.

Large scale businesses will definitely save much more. The use of bigger stretch wraps ensures that your business can handle all its packaging requirements without worrying about the depletion of packaging materials in the near future.

Another economic aspect is that the stretch wrap packaging application can easily be handled by humans and therefore no need to use capital intensive machines. This can be very beneficial to small and medium-sized companies that are labor-intensive.

Easy to Recycle

Not all packaging materials can be recycled. However, a stretch wrap is among the few materials that can be recycled at no extra cost to the business. Come to think of it, about 140,000 tons of stretch wraps go to waste when it comes to being recycled. It is time for business owners to take up their responsibility and ensure proper recycling systems are put in place to save both money and the environment.

Several Gauges to Suit Your Packaging Needs

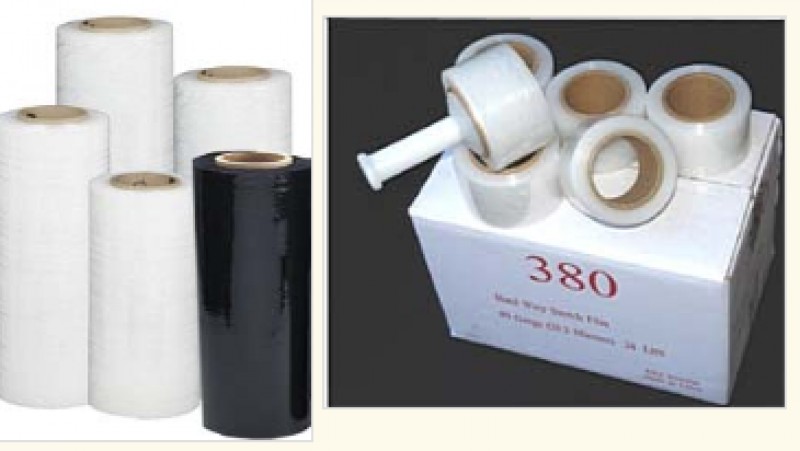

Stretch wraps come in different lengths and widths. This enables you to select the type of packaging material depending on what you want to store or transport. Here are some tips to consider

- Determine the weight and the height of the products you want to pack

- Select between a cast stretch wrap or a blown film

- Determine the specific

- amount of stretch filmsmaterial needed to cover the whole area of the product

- Use wraps of 60 gauge and below for products of 1300lbs and below and 150 gauges for products of up to 3500lbs.

Variety of Choices

Stretch wraps come in different varieties, which increase your options. The two most common but distinct varieties include the blown wrap and the cast wrap. The blown cover is made through the blown extrusion process, which leads to higher density and therefore, high quality. It is most appropriate for sharp objects or cumbersome products under transportation.

The cast wrap, on the other hand, is made through the cast extrusion process. It is a bit weak than the blown wrap and hence a little bit cheaper. It is mostly used to wrap light products with no sharp edges.